Package Integrity Testing

Package Integrity Testing

About Us

Introduction

In today’s fast-paced and highly regulated industries, ensuring the package integrity of medical, food, and pharmaceutical products is no longer optional—it’s essential. Package integrity testing validates whether packaging can protect contents against contamination, leaks, or mechanical damage throughout its lifecycle. From sterile medical pouches to shelf-stable food packs, a robust integrity testing strategy ensures safety, compliance, and brand trust. This article introduces the core concepts of package integrity, applicable testing methods, and how equipment from Cell Instruments supports high-precision integrity evaluations across industries.

Prefix describing what your business does will be here

Understanding Package Integrity Testing

01

What Is Package Integrity Testing?

Package integrity testing refers to a series of test methods designed to confirm that a package can maintain a secure, sealed environment—safeguarding contents from external contaminants, microbial ingress, or physical breach. This is especially critical in regulated sectors like pharmaceuticals, medical devices, food, and cosmetics.

Failures in package integrity can result in compromised product quality, loss of sterility, reduced shelf life, or consumer safety issues. For this reason, organizations rely on ASTM and USP <1207> container closure integrity guidelines to define and validate effective testing practices.

02

Why Integrity Testing Matters

Effective integrity testing supports:

-

Regulatory compliance (e.g., USP 1207, ASTM F1140, ASTM F2054)

-

Detection of material failure from sealing defects, poor film performance, or production inconsistencies

-

Evaluation of pressure resistance and seal strength under real-world stresses

-

Assurance that protective packaging functions as intended

By employing precise package integrity testing methods, manufacturers gain confidence that their packaging withstands the rigors of processing, transport, and storage.

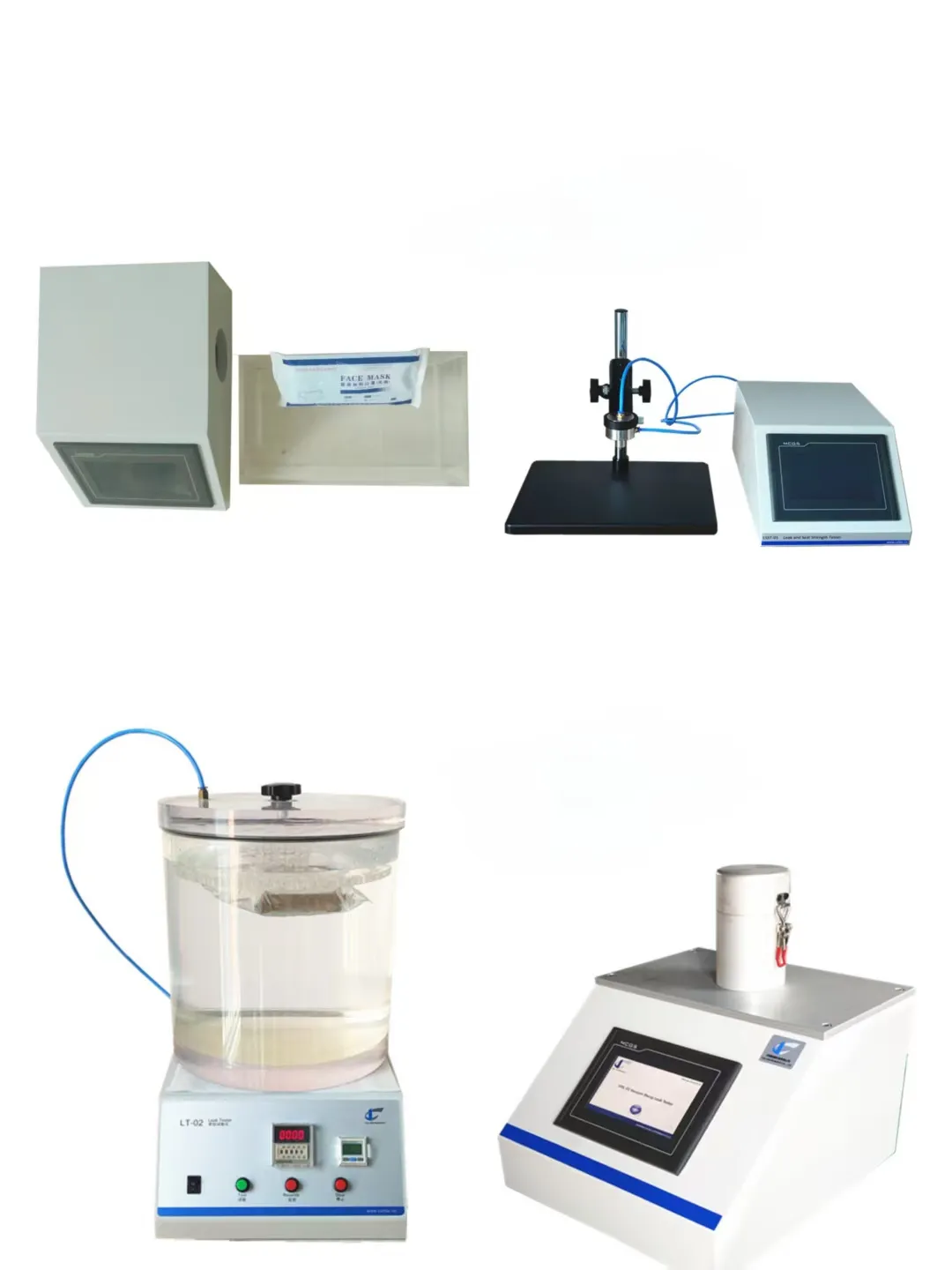

Key Package Integrity Testing Methods

Key Package Integrity Testing Methods

Strengthen Your Seal with Advanced Integrity Testing

Key Package Integrity Testing Methods

Package integrity testing is more than a compliance requirementit’s a proactive quality measure that directly impacts consumer safety and brand reputation. With trusted methods like burst testing, vacuum decay, and bubble leak detection, companies can detect even the smallest flaws in packaging systems.

1. Burst and Creep Testing (ASTM F2054)

Used to determine the maximum pressure a sealed package can withstand before rupturing. This destructive method helps quantify seal strength and detect structural weaknesses.

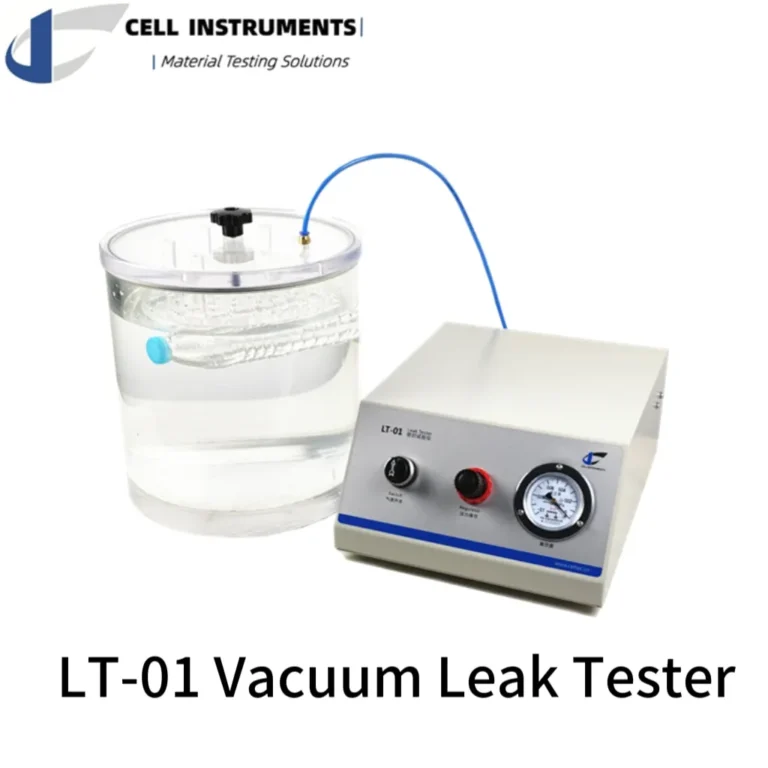

2. Vacuum Leak Testing (ASTM D3071)

A non-destructive method where the package is placed in a vacuum chamber filled with water. Leaks are identified via bubble emission caused by pressure differential.

3. Gross Leak Detection(ASTM F2096)

This method, often referred to as the submersion or dunk test, evaluates for visible gross leaks in pouches or sterile packages.

4. Vacuum Decay Method (USP <1207>)

A highly sensitive, quantitative method ideal for micro leak detection in sterile containers. This non-destructive test measures the pressure drop in a vacuum chamber after evacuation.

Playlist

Offerings

Step-by-Step Guide to Package Integrity Testing Methods

01

1. Burst and Creep Testing

Burst Test:

-

Connect the sample to the pressurization port using a suitable fixture.

-

Gradually apply internal air pressure via the tester.

-

Continue increasing pressure until the package ruptures.

-

Record the peak pressure at failure as the burst pressure.

Creep and Creep-to-Failure Test:

-

Set a constant pressure (typically 80–90% of burst pressure).

-

Maintain pressure over a defined period.

-

Observe the package for deformation (creep) or failure (creep-to-failure).

-

Record duration and failure data if applicable.

02

2. Vacuum Leak Testing

Test Procedure

-

Fill the test chamber with water and submerge the test sample.

-

Seal the chamber and initiate vacuum application.

-

Reduce pressure in the chamber to create a pressure differential.

-

Visually inspect for a continuous stream of bubbles from the package surface.

03

3. Gross Leak Detection

Test Procedure

-

Fill the test tank with water and immerse the test sample.

-

Connect the sample to a pressurization system.

-

Apply low internal pressure (typically 20–30 kPa) to create a pressure differential.

-

Observe the sample surface for continuous bubble emission.

-

Continuous bubbling indicates a gross leak.

-

-

Record leak location, pressure, and failure time.

04

4. Vacuum Decay Method

Test Procedure

-

Place the package in the sealed vacuum test chamber.

-

Begin the FILL stage: evacuate air to reach the target vacuum level.

-

Move to the SETTLE stage: allow stabilization of the system and sample.

-

Start the TEST stage: monitor the chamber for pressure increases.

-

Stable pressure = no leak

-

Rising pressure = potential leak

-

-

Proceed to the VENT stage: release vacuum and complete the test.

-

System automatically judges result as PASS or FAIL based on pressure variation thresholds.

How to Choose the Right Package Integrity Tester

Selecting the proper package integrity tester depends on: Package type (flexible vs. rigid, filled vs. empty) Desired test sensitivity (gross leak vs. micro leak) Regulatory requirements (e.g., ASTM or USP standards) Production stage (R&D, QC, line verification) A well-rounded integrity program may use multiple test methods for thorough evaluation—combining burst tests for pressure resistance, vacuum tests for leak detection, and decay methods for ultra-sensitive microleak analysis.

Frequently Asked Questions (FAQ) about Package Integrity Testing

1. What is package integrity testing?

Package integrity testing is a process used to evaluate whether packaging can maintain a secure seal to protect the product from contaminants, leaks, or mechanical damage. It ensures the packaging performs as intended throughout its shelf life and distribution cycle.

2. Why is package integrity testing important in pharmaceuticals and medical devices?

In regulated industries like pharmaceuticals and medical devices, package integrity testing is essential for patient safety, regulatory compliance (e.g., USP <1207>), and maintaining sterility. Any failure in the packaging system can lead to contamination or loss of efficacy.

3. What’s the difference between seal integrity testing and package integrity testing?

Seal integrity testing focuses specifically on the strength and consistency of the heat seal or closure system, while package integrity testing is a broader term that covers the entire packaging system, including material performance, seal quality, and resistance to external stress or pressure.

4. Can package integrity testing detect microleaks?

Yes, microleaks can be detected using high-sensitivity methods such as the vacuum decay method (as defined in USP <1207>). Instruments like the MLT-01 Micro Leak Tester from Cell Instruments are specifically designed for this purpose.

"Ensure your packaging performs when it matters most. Partner with Cell Instruments—your seal of integrity."

– Cellinstruments

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985